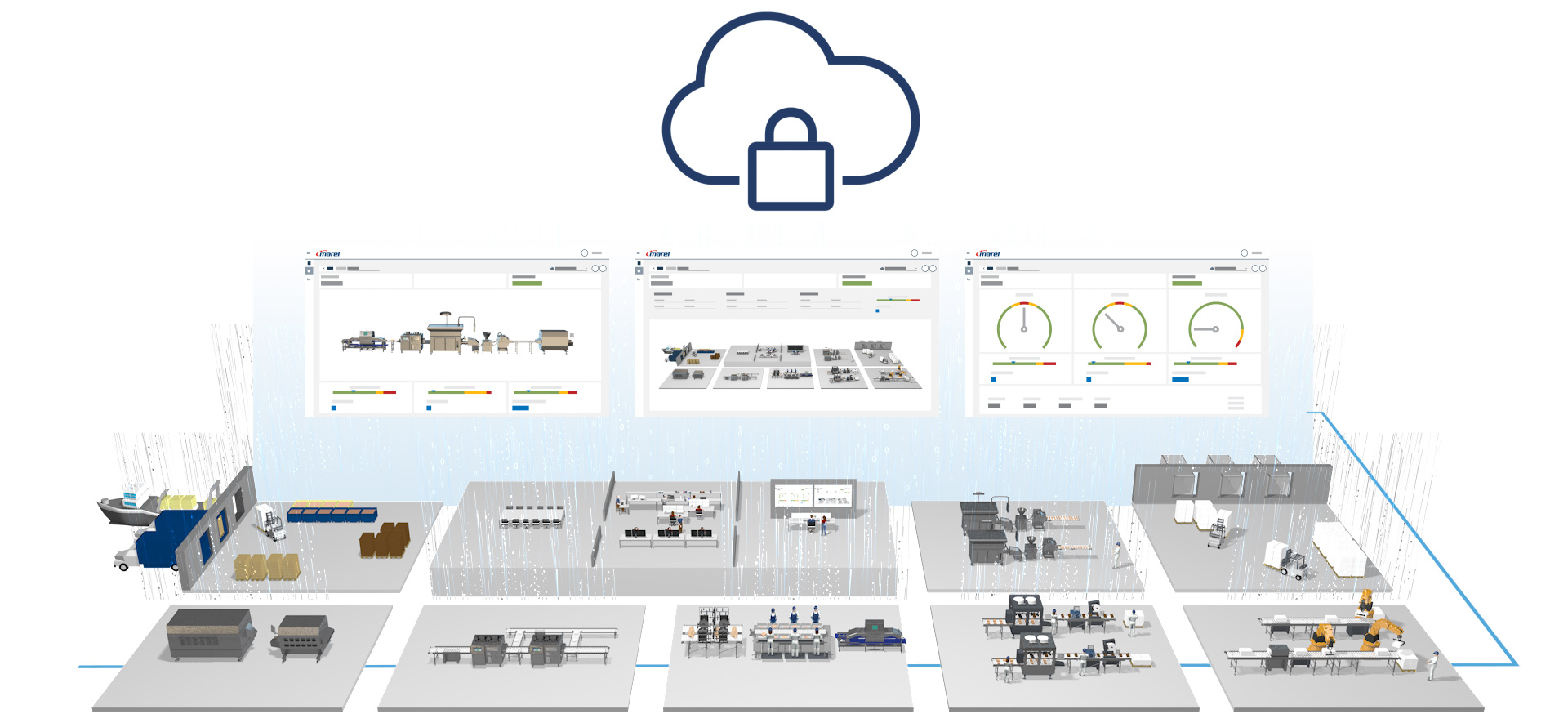

Connecting machine to service through software, to unlock data-driven operations to reach your food production’s full potential.

Guided self-service – non-consultancy

A growing number of machines in our portfolio come with machine monitoring software built-in and ready to activate. Via the web portal you can access current and recent machine health and production data, such as temperature, pressure, throughput, weight, and other key metrics.

Consultancy

Utilizing the in-built machine monitoring capabilities, Consultancy is a connected services subscription model service that offers dedicated service agreements tailored to your operation. Our experts work with you to develop maintenance strategies based on your specific equipment data and service needs.

Contact the team to discuss Advanced options that can maximize your machine uptime and effectiveness.