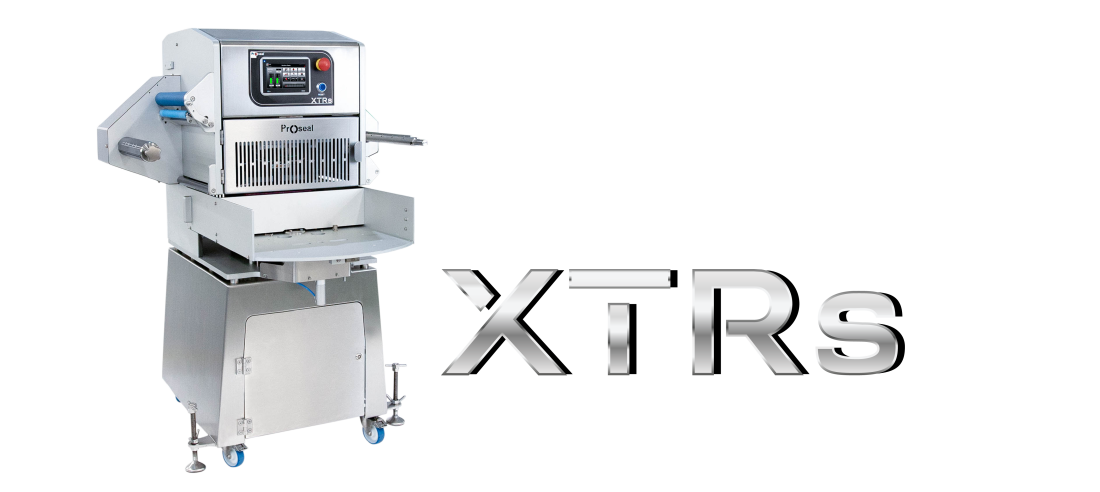

Seeking a tray sealer that saves on energy without sacrificing speed? JBT Marel Proseal's recently-introduced XTRs tray-sealing machine is a semi-automatic, two-station solution capable of sealing 30 packs per minute, but with lower energy usage and total running costs.

Energy-efficient tray-sealing: why JBT Marel Proseal's solutions make high speed savings

04 May 2024

With a commitment to innovation and excellence, Proseal has been at the forefront of the packaging industry for over two decades and this is reflected in the revolutionary capabilities of the XTRs.

The successor to the GTR, the XTRs features a 2-impression tool and employs all-electric sealing to create a more consistent and efficient seal force.

The XTRs' user-friendly design includes integrated HMI with multi-language settings, recipe driven control and an automatic tool lock. Quick release tooling also enables the user to switch from one tray size to another in less than five minutes.

Fully portable with an automatic film-feed, the machine has an option for running Modified Atmosphere Packaging (MAP) to enable extended shelf life. It also can run printed film and link to printers for the impression of codes or data onto the film.

According to Proseal's director of sales and marketing, Sandra Driver, the innovative solution underscores the company's "commitment to delivering best-in-class packaging solutions" that enable customers to enhance productivity, streamline operations, and maximize profitability.

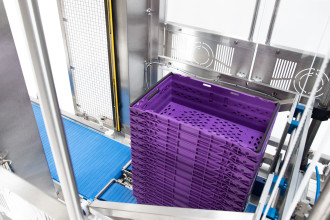

The CDS: reducing repetition

Another recently-launched solution from JBT Marel Proseal is the CDS Case De-Stacker, a fully automated system which reduces repetitive manual handling by automatically de-stacking cases and delivering them to the case packing machine. Capable of de-stacking 35 cases per minute, the CDS can handle both RPC and cardboard cases of all standard sizes on the same machine, utilizing quick change tooling and a recipe driven control system.

Taking less than a minute to change product, the length of the CDS feed conveyor can be configured to suit any application giving up to an hour of operation before reloading.

“By automating the de-stacking process, we're not just complementing our award-winning case packing equipment, we’re revolutionizing packaging efficiency,” says JBT Marel Proseal’s Product Line Manager for End of Line Solutions, Nick Severn.

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.