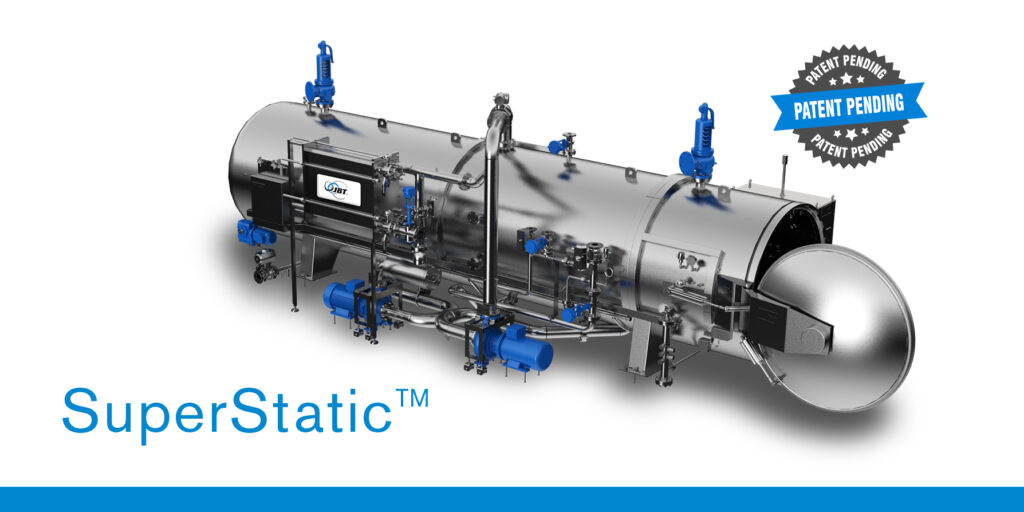

In the bustling region of Asia-Pacific where innovation meets tradition, one of our esteemed clients has been leveraging JBT's A186 retorts for over two decades to produce their popular coffee drink. As they embark on an exciting new Greenfield project adjacent to their existing factory, they are set to install four of our state-of-the-art A186-SuperStatic (A186-SS) retorts. This new installation promises to elevate their production capabilities to new heights.

Brewing success: JBT's A186-SS retorts in APAC's coffee drink revolution

16 May 2025

The legacy of A186

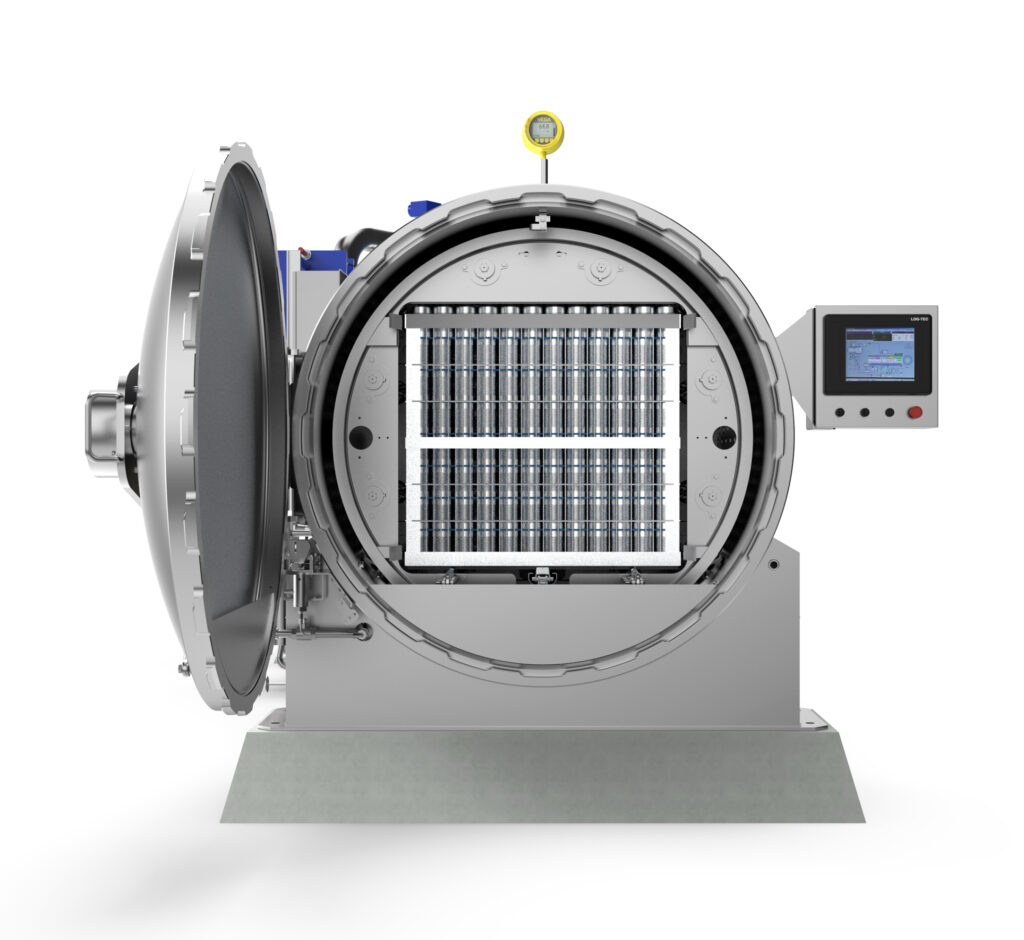

The original A186 retorts, have been a cornerstone of our client's production line, offering a flow rate of approximately 230 m³/hr. These retorts have been instrumental in processing coffee drinks in cans of 180/200 ml and 250 ml, ensuring consistent quality and taste that consumers have come to love.

Enter the A186-SuperStatic

The new A186-SS retorts are designed to enhance production efficiency and product quality. With an impressive flow rate of approximately 560 m³/hr, these retorts are engineered to meet the demands of modern food processing.

Key comparisons: A186 vs. A186-SS

Temperature distribution:

- A186: The original retorts have provided reliable temperature distribution, ensuring that each can is evenly heated. However, with advancements in technology, the A186-SS takes this to the next level.

- A186-SS: The SuperStatic retorts boast superior temperature distribution, reducing temperature gradients and ensuring even more consistent heating across all cans. This improvement is critical for maintaining the delicate balance of flavors in coffee drinks.

Heat penetration:

- A186: Known for its robust heat penetration, the A186 has been effective in ensuring the core of each can reaches the required temperature for safe consumption.

- A186-SS: The enhanced design of the A186-SS allows for faster and more uniform heat penetration. This not only improves the safety and quality of the product but also reduces processing time, increasing overall efficiency.

Looking ahead

As our client in Asia Pacific integrates these new A186-SS retorts into their coffee drink production line, they are poised to continue their legacy of delivering high-quality coffee drinks to their consumers. The combination of improved temperature distribution and heat penetration ensures that every can meets the highest standards of safety and taste. This Greenfield project marks a significant step forward in food processing technology, reinforcing JBT's commitment to innovation and excellence. We are excited to support our clients in their journey toward greater efficiency and sustainability in the dynamic Asia Pacific market.

Learn more about SuperStatic retorts

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.